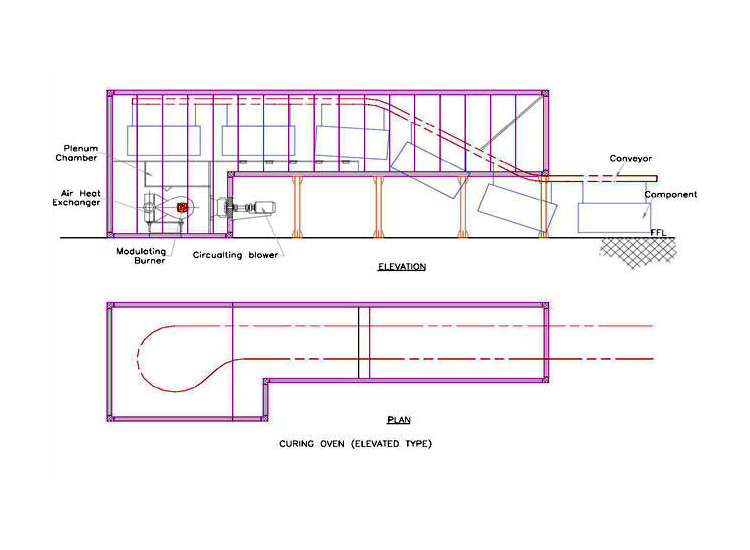

The powder/liquid curing process calls for very accurate and uniform temperature all over the components. The metal has to attain the desired temperature and then should be there for specified time keeping the same temperature. This is very critical and difficult to maintain in ground-mounted ovens as there would be leakages. Keeping this is one of the criteria; we always propose elevated curing ovens. The space occupied and the conveyor length requirement will increase in this proposition, but the advantages are profitable. However, we also supply ground-mounted ovens.

The modular constructed will male-female type insulated GI panels and internal GI Plenum chamber to equalize the circulating hot air pressure. This will ensure maximum heat transfer to the components, and minimum heat transfer to outside atmosphere.

The heat source can be Electrical, Diesel fired, LPG fired or any other special fuel. We have the designs to get maximum efficiency out of the system. The elevated ovens will have the permanent openings in the entry and exit side. However, air seal does not allow the hot air to escape out of the system. We use modulating burner by which you will be able to get accurate readings in the oven and also a fuel efficient oven. The maximum temperature shall be 2600C. The thickness of the insulated panel would be 150mm with 96 kg/m3 rock wool density.

The controls are provided to control heaters/modulating burners, circulating hot air blowers, and temperature.