Usage of the cartridge for recovery is a newer technology. But choosing the correct cartridge for powder recovery is very critical. We stress upon only paper cartridge filter with pleating and the specification is each cartridge is capable of handling 1200 CMH of air. However, depending on the suction capacity of the blower the number of cartridges shall be derived. Here the powdered particle (both heavier and finer) hits the outer surface of the cartridge and gets filtered. The air will get sucked into the inner tube of the cartridge. The cartridge system need to have a reverse pulse cleaning system. The reverse pulse cleaning sends pulses of compressed air at a very high velocity into the inner tube of the cartridge. This make the powder to fall into the collection hopper and cleans the pores of the cartridge. Here the recovery efficiency is 98 to 99.99% Max. The only drawback is, you need to have a separate set of cartridges for each color. This means more investment. But the booth cleaning time reduces drastically compared to the cyclone recovery system. The system resistance is less compared to cyclone recovery and the power consumption is less when in comparison.

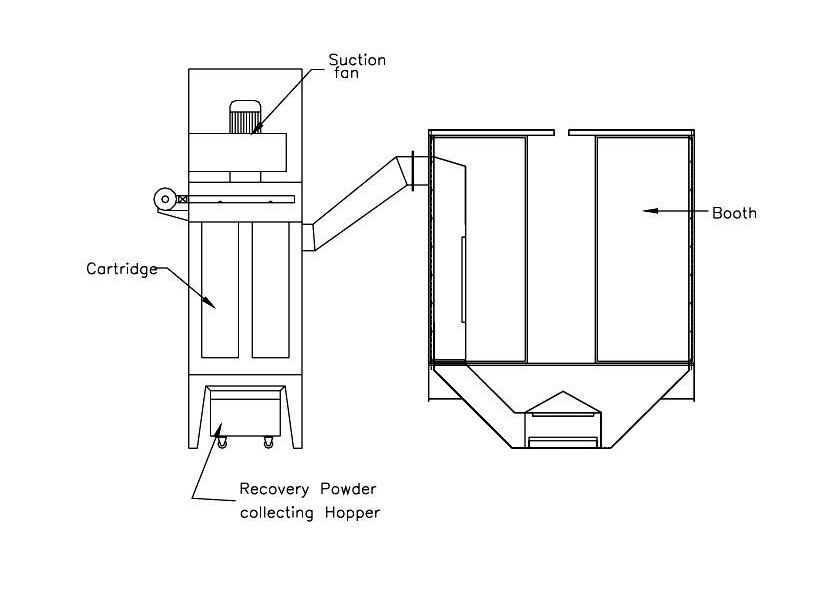

A typical booth with Multi-cyclone recovery and Cartridge after filter system is shown on the right Side: