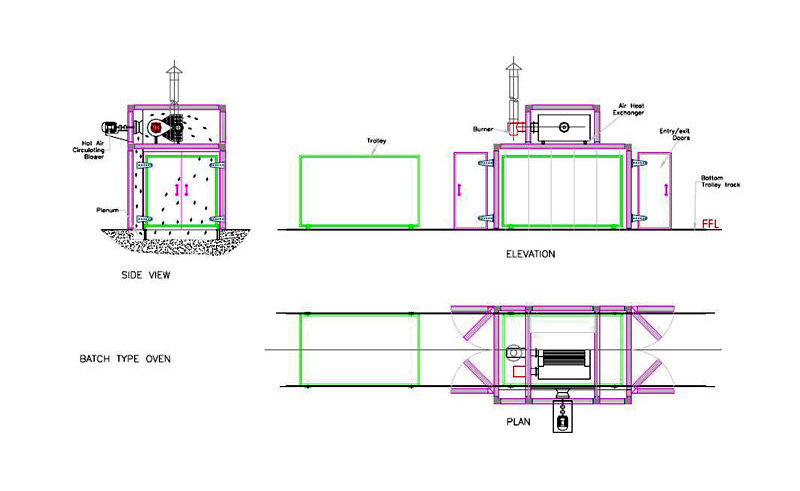

The job coaters or sometimes even OEM’s choose batch type ovens. There are several reasons for the same. But one of the major reasons does not know the component geometry/size. In this type, the trolley, the material handling system, will carry the component inside the oven. The entry/exit doors are closed and then the system will be switched on. In this system, controls are provided to control the batch time, temperature and the air pressure inside the oven.

The modular constructed will male-female type insulated GI panels and internal GI Plenum chamber to equalize the circulating hot air pressure. This will ensure maximum heat transfer to the components and minimum heat transfer to outside atmosphere.

The heat source can be Electrical, Diesel fired, LPG fired or any other special fuel. We have the designs to get maximum efficiency out of the system. The batch type ovens will have the permanent openings in the entry and exit side with the facility for closing the door. There would be a bottom track to facilitate smooth movement of the trolley. The maximum temperature shall be 2600C. The thickness of the insulated panel would be 150mm with 96 kg/m3 rock wool density.

The controls are provided to control heaters/modulating burners, circulating hot air blowers, and temperature.